Featured Products

INQUIRY NOW

New Products

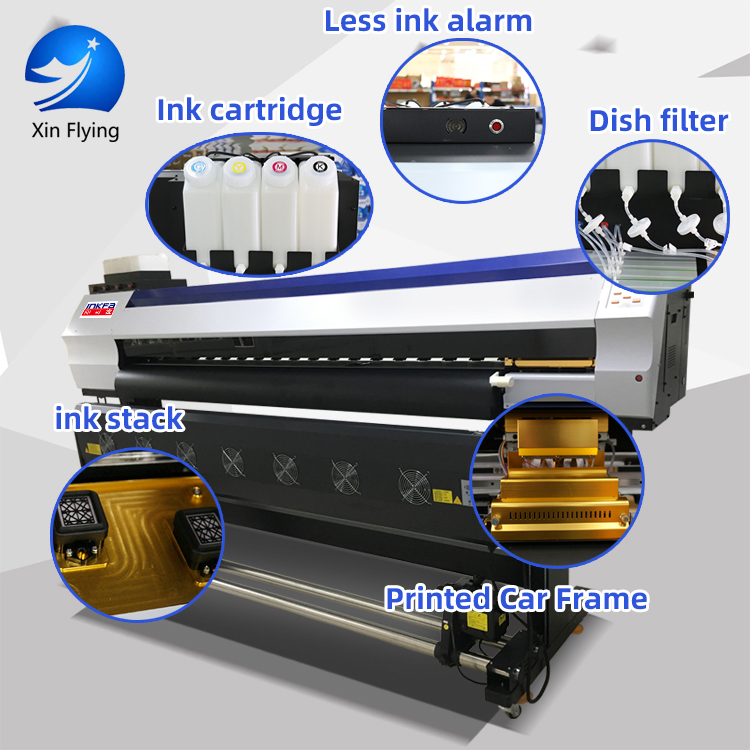

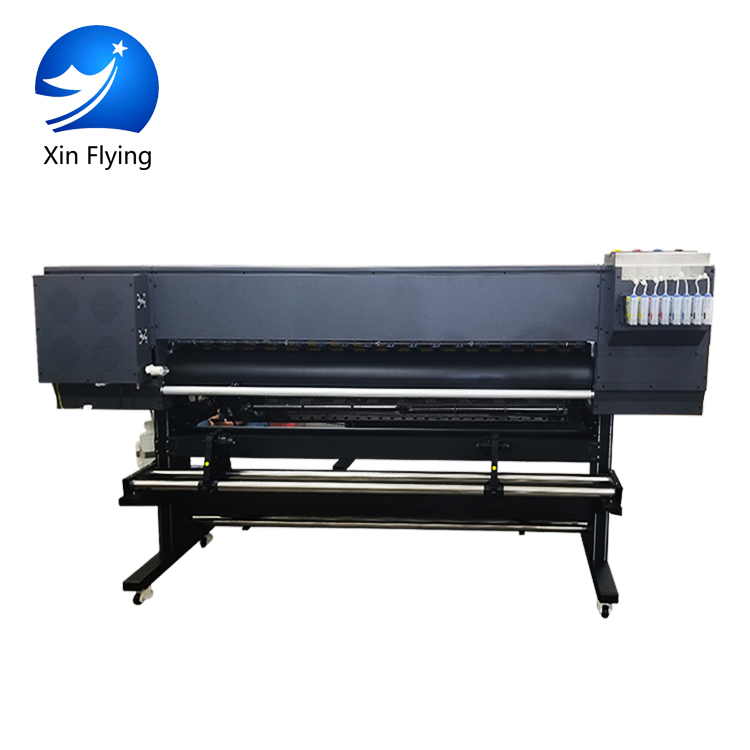

Digital Indoor Plotter Poster Wallpaper Eco Solvent Printing Machine

Competitive Price Digital Printing Machine 1.6m with Dx5 Printhead

Tecjet Dx5 Printhead Eco Solvent Printer for PVC Banner Printing

1.6m 1440dpi Flex Banner Eco Solvent Printer with Dx5 Print Head

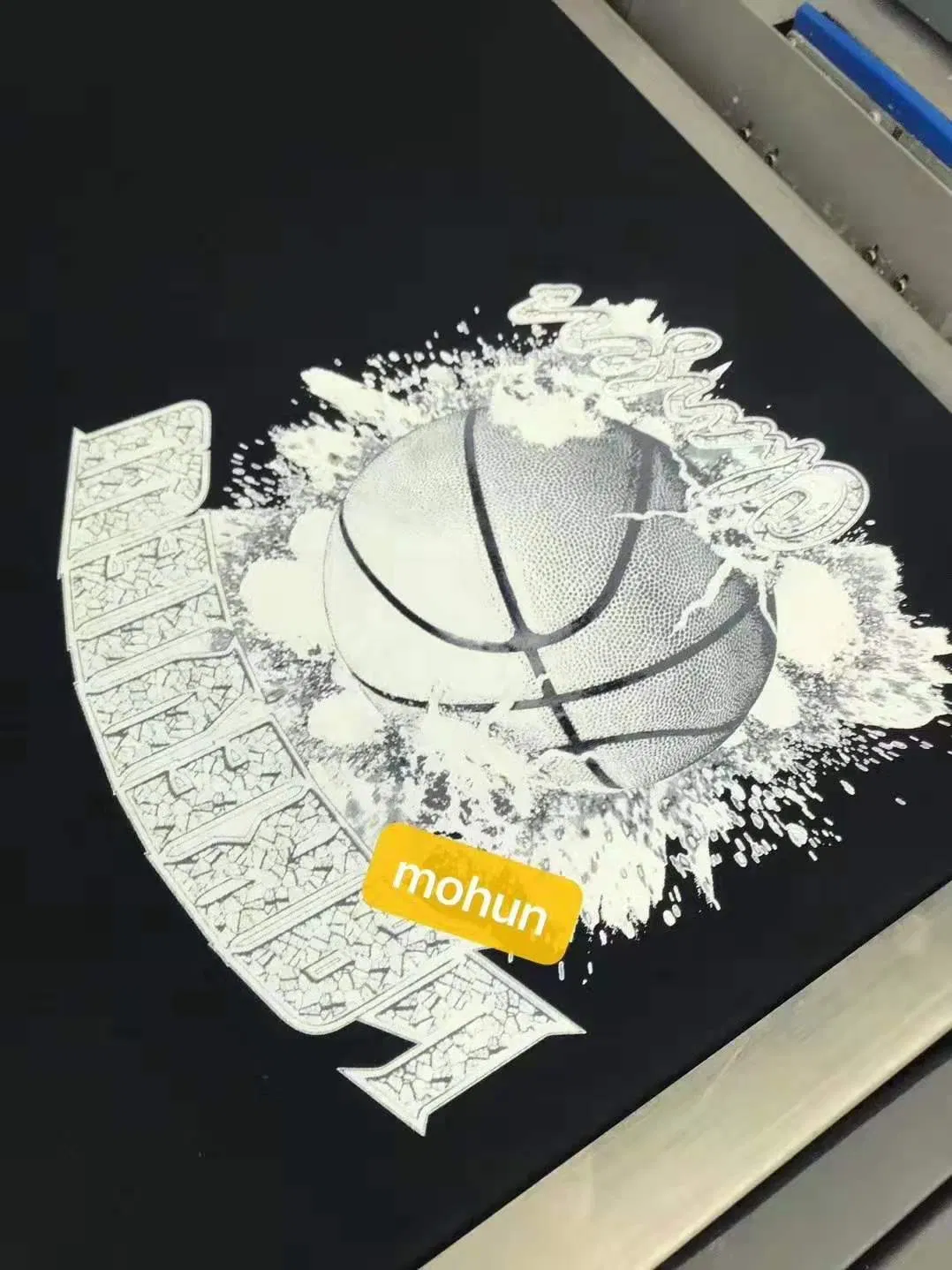

Xinflying Lifetime Warranty Dye Sublimation Printer Large High Speed Sublimation Printer

Guangzhou Sublimation Printer Inkjet Large Format with Clothes

120m² /Hsublimation Inkjet Printer Sublimation Printer Machine Dye