How Control Valve Actuator get a high-quality work?

2025-08-18

When it comes to industrial automation, one component stands out for its critical role in regulating fluid flow—the Control Valve Actuator. Whether you're in oil and gas, water treatment, or chemical processing, understanding how these devices work and what makes a high-quality actuator can significantly impact your operations.

How Does a Control Valve Actuator Work?

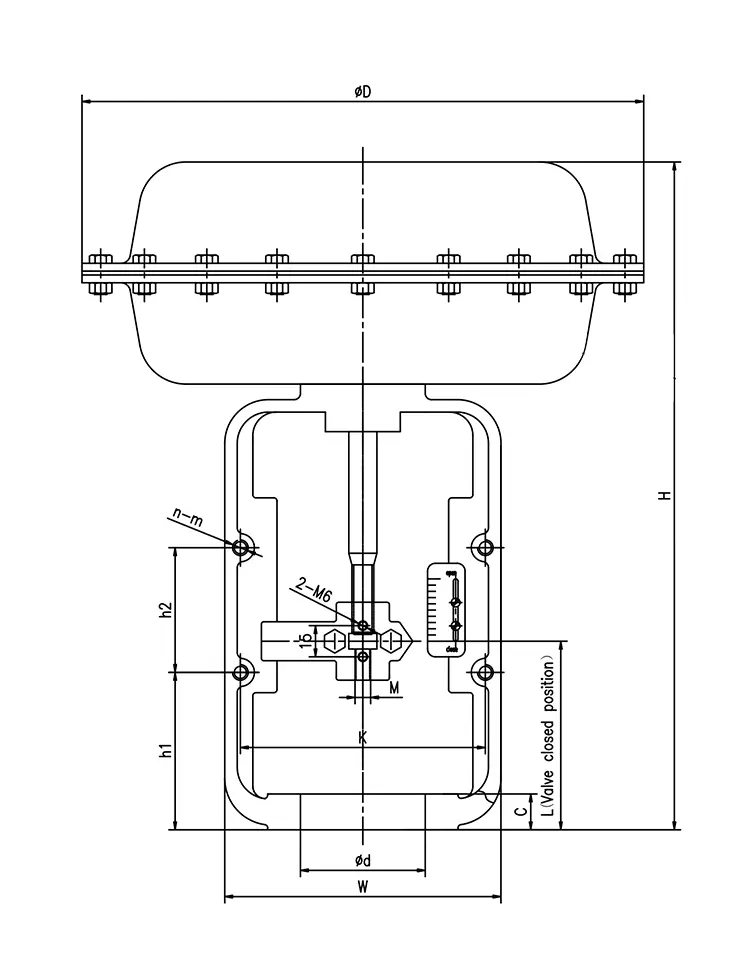

A Control Valve Actuator is the driving force behind a control valve, converting energy (pneumatic, electric, or hydraulic) into mechanical motion to open or close the valve. The actuator responds to signals from a control system, ensuring precise flow regulation. For instance, in a pneumatic actuator, compressed air pushes a diaphragm or piston, which then moves the valve stem. Electric actuators, on the other hand, use motors to achieve the same effect with higher precision.

Key parameters to consider when selecting a Control Valve Actuator include:

| Parameter | Description |

|---|---|

| Type | Pneumatic, Electric, Hydraulic |

| Torque/Speed | Determines actuation speed and force (e.g., 50 Nm at 90° in 10 seconds) |

| Operating Pressure | Max pressure the actuator can handle (e.g., 100 psi for pneumatic models) |

| Material | Stainless steel, aluminum, or engineered plastics for corrosion resistance |

| IP Rating | Ingress protection level (e.g., IP67 for dust and water resistance) |

| Fail-Safe Mode | Spring-return or double-acting for emergency shutdowns |

Common Questions About Control Valve Actuators

Q: What’s the difference between pneumatic and electric actuators?

A: Pneumatic actuators use compressed air for quick, high-force movements, making them ideal for hazardous environments. Electric actuators offer finer control and are better for precision tasks but may require more maintenance in dusty or wet conditions.

Q: How do I choose the right actuator for my valve?

A: Consider factors like required torque, operating environment, and fail-safe needs. For high-pressure systems, hydraulic actuators might be best, while electric actuators suit applications needing programmable control.

Why Precision Matters in Control Valve Actuators

In industries where even minor deviations can lead to significant inefficiencies or safety risks, the Control Valve Actuator must deliver reliability. Advanced models now feature smart technology, integrating IoT for real-time monitoring and predictive maintenance.

Trusted Performance with Lozose

At Lozose, we engineer Control Valve Actuators that meet stringent industrial demands. Our products combine durability with cutting-edge automation features, ensuring seamless integration into your systems.

For more details or to discuss your specific needs, contact us today—our experts are ready to help you optimize your flow control solutions.