How Does a Folder Gluer Machine Improve Packaging Efficiency?

2025-09-04

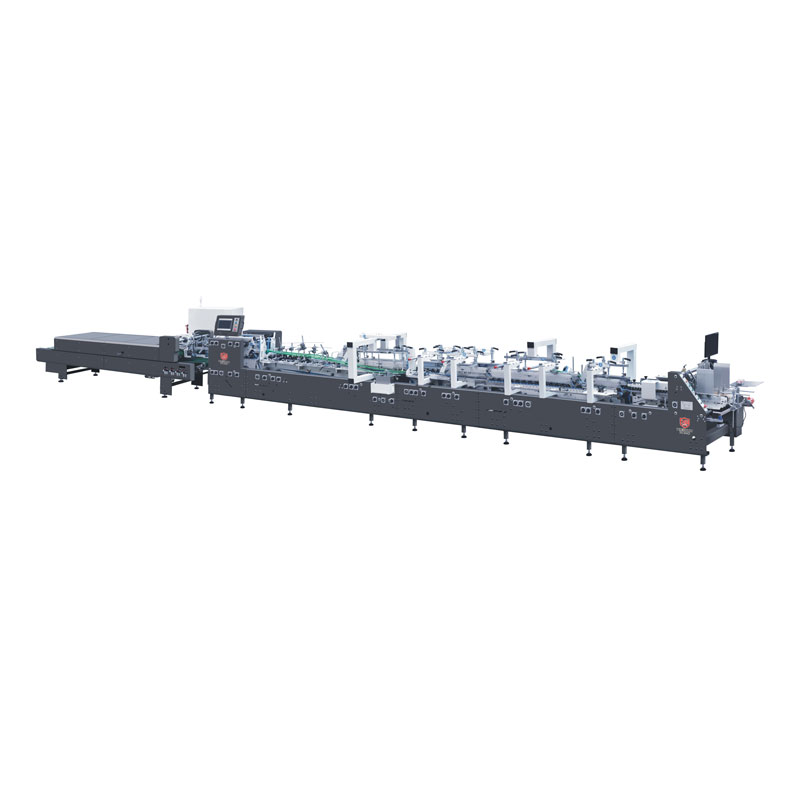

In today’s fast-paced packaging industry, businesses are under constant pressure to enhance productivity, maintain superior quality, and meet strict delivery deadlines. Among the essential pieces of equipment transforming packaging lines, the Folder Gluer Machine plays a pivotal role. From folding and gluing cartons with precision to streamlining high-volume production, this machine is a key driver of efficiency and consistency in modern packaging.

What Is a Folder Gluer Machine and How Does It Work?

A Folder Gluer Machine is a specialized piece of equipment used in the packaging industry to fold and glue paperboard or corrugated cartons. It automates what used to be a labor-intensive, time-consuming process, ensuring speed, precision, and uniformity.

Types of Folder Gluer Machines

| Type | Suitable Materials | Speed Range | Typical Applications |

|---|---|---|---|

| Straight Line Gluers | Paperboard, lightweight card | 200-500 m/min | Cosmetic boxes, food packaging, medicine cartons |

| Crash-Lock Bottom Gluers | Corrugated and folding cartons | 150-350 m/min | E-commerce boxes, bakery packaging, toy cartons |

| 4/6 Corner Gluers | Heavy-duty cartons | 100-250 m/min | Premium packaging, beverage cartons, gift boxes |

Why Should Businesses Invest in a Folder Gluer Machine?

Investing in a Folder Gluer Machine isn’t just about speed—it’s about transforming your packaging process to meet modern demands. Here are the key benefits that make this machine an essential asset:

Increased Production Efficiency

A folder gluer machine can produce 20,000 to 40,000 cartons per hour depending on the model. For businesses handling high-volume packaging orders, this translates to significant time savings and reduced labor costs.

Superior Folding and Gluing Precision

Advanced sensors and servo-driven systems ensure precise folding angles and accurate glue placement. This consistency minimizes rejects and improves the quality of the final product, which is vital for industries like pharmaceuticals and cosmetics.

Flexibility for Multiple Packaging Styles

Modern machines support various carton styles, including:

-

Straight-line cartons

-

Crash-lock bottoms

-

4-corner and 6-corner designs

-

Special-shaped packaging

This versatility allows businesses to adapt quickly to changing client requirements without investing in multiple machines.

Cost Reduction and Waste Control

-

Automated feeding reduces material wastage.

-

Glue-saving technology ensures optimal adhesive usage.

-

Less manual labor lowers operational costs.

Enhanced Safety and Reliability

Built-in safety mechanisms, emergency stop functions, and anti-jam technology reduce the risk of accidents and equipment damage, ensuring a safer working environment.

Technical Specifications and Product Features

Choosing the right folder gluer machine depends on your production scale, carton types, and desired efficiency. Below is an overview of the standard specifications for high-performance models:

| Feature | Specification |

|---|---|

| Max. Speed | Up to 450 meters per minute |

| Material Compatibility | 200gsm – 800gsm paperboard, E/F/N-flute corrugated board |

| Max. Folding Size | 1200mm x 800mm |

| Min. Folding Size | 60mm x 80mm |

| Glue Type | Hot-melt, cold glue, or dual system |

| Control System | PLC touchscreen interface with memory presets |

| Automatic Detection | Fault detection, glue sensors, double-sheet detection |

| Energy Consumption | 12–18 kW depending on model |

Practical Applications and Industry Use Cases

The versatility of a folder gluer machine makes it suitable across multiple sectors. Let’s look at some industry-specific applications:

Food and Beverage Packaging

From cereal boxes to beverage cartons, folder gluer machines ensure high-speed, hygienic, and reliable packaging for products that require strict quality standards.

E-Commerce and Shipping Boxes

With the growth of online retail, demand for crash-lock bottom cartons and corrugated packaging has skyrocketed. Folder gluer machines meet these demands efficiently.

Cosmetic and Pharmaceutical Packaging

Premium packaging for cosmetics and medicines requires flawless folding and precise gluing to maintain brand integrity and product safety.

Luxury and Specialty Packaging

4/6 corner folder gluers create intricate cartons for luxury items such as chocolates, perfumes, and premium gifts, meeting the highest aesthetic and structural standards.

Frequently Asked Questions (FAQs)

Q1: What factors should I consider when choosing a folder gluer machine?

A: Consider your production volume, carton types, material thickness, available space, and automation level. A straight-line gluer suits high-speed runs, while a 4/6 corner gluer offers flexibility for complex packaging.

Q2: How can I maintain a folder gluer machine for optimal performance?

A: Regular maintenance is crucial. Clean glue nozzles daily, lubricate moving parts weekly, calibrate sensors periodically, and schedule professional servicing to extend the machine’s lifespan and maintain top performance.

A Folder Gluer Machine is a cornerstone of modern packaging production, combining speed, precision, and versatility to meet evolving market demands. By automating folding and gluing processes, businesses can reduce labor costs, minimize errors, and deliver consistent, high-quality packaging solutions. Whether you’re in e-commerce, food and beverage, pharmaceuticals, or luxury goods, investing in the right machine can transform your production capabilities and enhance customer satisfaction.

At NEW STAR, we specialize in providing advanced folder gluer machines tailored to diverse industry needs. Our models integrate cutting-edge automation, intuitive controls, and superior build quality to maximize efficiency and reliability.

Contact us today to explore our latest folder gluer solutions and find the perfect fit for your packaging requirements.