What Advantages Are Driving Automatic Coating Machines?

2025-10-27

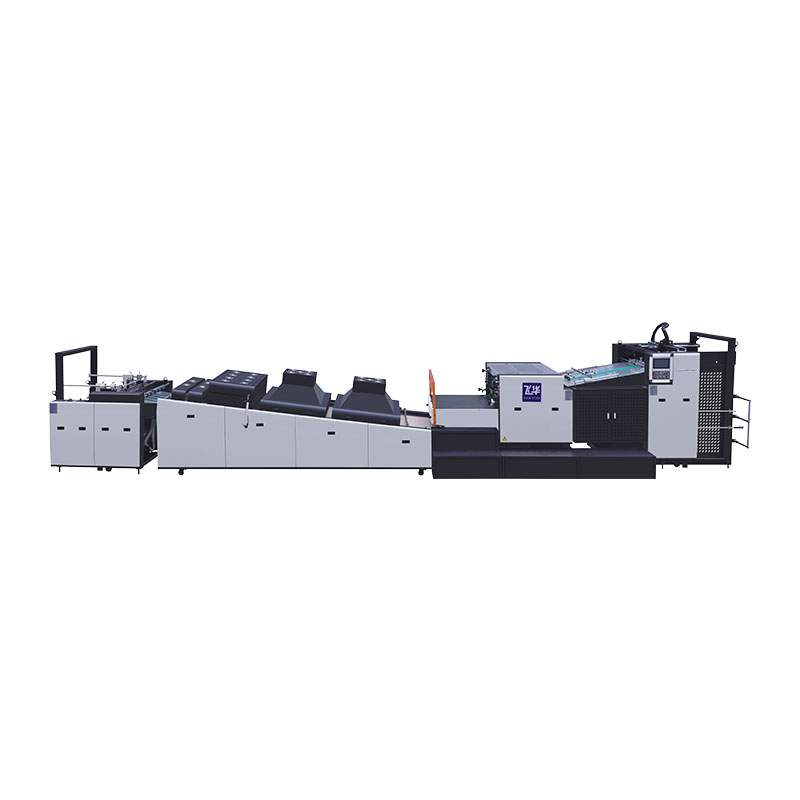

A high-efficiency automatic coating machine is engineered to apply a consistent, uniform film or coating layer to substrates (such as screens, tablets, metal parts or meshes) in an industrial process. In this article, the focus is on the machine’s key advantages, its core functions, how it operates, and the future trends influencing its adoption in manufacturing. The centre of the discussion is a professional overview of the automatic coating machine’s parameters, benefits and application value for production-line users.

What Is an Automatic Coating Machine, and What Are Its Core Specifications?

An automatic coating machine (henceforth “the machine”) refers to equipment which automates the process of applying a coating solution (film, emulsion, protective layer, sugar-coat, solvent-based or water-based) onto a target substrate, with precise control over layer thickness, uniformity, drying, curing and production speed. Its automation reduces manual labour, improves repeatability, reduces waste and increases output quality.

Below is a summary of professional spec parameters typically found in such machines:

| Parameter | Typical Value / Range | Notes |

|---|---|---|

| Maximum Frame or Substrate Size | e.g. 1050 × 1250 mm (for screen mesh) | Indicates maximum width/height that can be coated. |

| Coating Speed | 10–100 mm/sec (digital setting) | Speed at which coating head moves across substrate. |

| Power Consumption | e.g. 0.33 kW for small unit | Reflects energy requirements for the machine. |

| Machine Weight / Dimensions | e.g. 340 kg; 1830 × 530 × 1900 mm | Useful for footprint planning and installation. |

| Pan or Drum Diameter (tablet or film coating version) | e.g. Ø 380 mm; rotation speed 4–30 rpm | Pertains to pharmaceutical film coating variant. |

| Control System | Touch-screen/HMI with digital control, recipe management | Facilitates repeatable production runs and tracking. |

These parameters illustrate the machine’s versatility and complexity, spanning from film/emulsion application for screen-printing meshes to tablet/sugar coating in the pharmaceutical and food sectors. The automatic coating machine we are introducing in this text shares similar high-precision control, digital interface, adjustable speed and thickness control, and is suitable for integration in production lines seeking consistency and higher throughput.

Why Should Manufacturers Invest in Automatic Coating Machines?

Several key drivers make investment in automatic coating machines attractive to manufacturers across sectors (printing, electronics, pharmaceutical, food, packaging). These drivers include:

-

Consistency & Uniformity of Coating

Automation ensures uniform layer thickness, reducing defects such as uneven coating, drips, bubbles or variations in film build-up. For instance, modern machines include features like pressure regulation, servo-driven control and digital settings to achieve high precision. -

Increased Throughput and Reduced Labour

By automating loading, coating, unloading and cleaning (in some versions CIP – Clean-In-Place systems) the machine cuts down production cycle time and labour cost. As noted in pharmaceutical-oriented systems: “a semiconductor front panel” style interface and automated discharge increase ease of use. -

Material & Waste Savings

Precise spraying/nozzle configuration, controlled film build and reduced overspray or wasted coating material lead to lower consumption of coating liquids and less cleanup. For example, one user guide mentions a smart spray system to prevent coating material waste. -

Better Quality Control and Compliance

Especially for highly regulated sectors (pharmaceutical, food), automatic coating machines support good manufacturing practice (GMP) standards, record recipes, adjust parameters consistently and thus support quality assurance. -

Future-proofing Production Lines

As production requirements demand faster cycles, thinner coatings, multi-layer films, and flexible batch sizes, using an automatic coating machine becomes a strategic asset. The machine supports recipe memory, repeat runs and minimal manual adjustment, which is critical for evolving production demands.

Given these drivers, manufacturers looking to improve product finish, reduce costs, scale up output and maintain high quality are strongly motivated to integrate automatic coating machines. The machine described here provides these advantages and positions the user for future manufacturing upgrades.

How Does the Automatic Coating Machine Work – Functions, Workflow and Best Practices?

Understanding how the machine operates is essential for optimal integration and maximising its benefits. The workflow and functional elements can be broken down as follows:

-

Loading the Substrate

The substrate (mesh frames, tablet batches, metal parts etc) is loaded into the machine. For example, loading may be via clamps, a slide-in frame, or a rotary drum. In screen-print emulsion machines the frame is fixed and then the coating head moves across it. -

Coating Application

The machine applies the coating liquid via a spray head, or in some types by roller or curtain. The coating speed and number of passes can be preset (e.g., 1-15 times front/back) in digital machines.The pressure, flow and thickness control are integral: e.g., “coating pressure equalizing control system” was applied in a high-precision model. -

Drying / Curing / Exhaust

After coating, air supply, hot air or exhaust systems dry or cure the coating layer. A well-designed machine has an effective air supply/exhaust structure to maximise drying efficiency.Correct drying avoids defects such as flaking or pooling, ensuring adhesion and surface finish. -

Unloading / Cleaning

Once coating and drying are complete, the substrate is unloaded. Many machines include CIP systems (clean-in-place) or automated unloading features to reduce manual cleaning time. For example: “The one distinctive feature … HVLP spray gun … cleaning … system…” in the tablet coater context. -

Control & Recipe Management

The operator uses an HMI or PLC touch-screen to set parameters: coating speed, layer count, waiting time, drying temperature, etc. The machine may allow saving and recalling recipes for repeat jobs, reducing setup time and human error. -

Maintenance and Monitoring

Sensors, alarms and monitoring functions help detect issues (e.g., uneven spray, pressure drop, airflow issues). A good machine supports quick maintenance and cleaning access. Example: digital manometer/pressure display on touch screen for quick monitoring.

Best Practice Tips for Operation

-

Ensure the substrate is clean and properly fixed before coating begins so that movement does not cause smearing or unevenness.

-

Choose the correct number of passes and spray settings for the coating material and target thickness — over-applying can cause runs, pooling or cracking.

-

Monitor the drying/curing phase carefully — insufficient drying time or inadequate airflow can lead to adhesion issues or flake-off.

-

Use the machine’s recipe memory to save past successful settings — this accelerates repeat production jobs.

-

Schedule regular maintenance of spray nozzles, air filters and exhaust fans to ensure consistent performance.

By following these functional steps and operational best practices, the automatic coating machine can deliver high-quality coating results with minimal manual intervention, consistent output, and lower waste.

What Future Trends Will Shape the Development and Adoption of Automatic Coating Machines?

To stay ahead in manufacturing, understanding the upcoming trends in automatic coating machines is crucial. Several key themes are emerging:

-

Thin Film and Precision Layer Control

As demand grows for thinner coatings, multi-functional films (anti-microbial, anti-scratch, conductive, water-repellent), machines will need to deliver increasingly precise layer thicknesses, micro-meter control, and advanced coatings. The trend toward high‐precision equipment in sectors such as electronics and medical devices will drive this. -

Digital, Connected and Smart Manufacturing Integration (Industry 4.0)

Machines will increasingly offer connectivity (IoT), data logging, predictive maintenance, and integration with MES/ERP systems. Recipe tracking, remote monitoring and analytics will become standard. This supports better process control, traceability and optimisation. -

Flexible Batch Sizes, Quick Changeovers

Manufacturers are moving toward more customised, smaller batch runs rather than large homogeneous production. Automatic coating machines will need to support rapid change-over of substrates/coatings, modular design and easier cleaning to enable flexible manufacturing. -

Energy Efficiency and Environmental Compliance

With rising regulatory pressure and sustainability targets, machines will need improved energy efficiency, minimal waste (material, overspray, cleaning solvents), and safer operation (reduced emissions, better air filtration). For example, air supply and exhaust systems (as seen in the pharmaceutical variant) are becoming more sophisticated. -

Multi‐Functional Coatings & Additive Manufacturing Synergies

With coatings evolving to include functionalities (e.g., conductive inks, antimicrobial layers, thin optical films), coating machines will need to adapt to new materials, multi-layer processes, integration with robotics and downstream curing or inspection. The synergy between coating machines and additive manufacturing will accelerate. -

Globalisation & Standardisation

As manufacturers seek global markets, machines that meet worldwide standards (e.g., GMP, ISO, environment) and offer multi-language HMI, remote support and modular spare-parts will gain favour. Automated coating machines that support standard workflows and compliance will be preferred.

In summary, the future of automatic coating machines lies in high precision, digital integration, flexibility, sustainability and support for advanced coating materials. The machine being described is well positioned to meet these trends by offering digital control, recipe management, high accuracy of layer application and support for efficient cleaning and maintenance.

Frequently Asked Questions (FAQ)

Q: What types of substrates can an automatic coating machine handle?

A: An automatic coating machine can be configured to coat a wide variety of substrates — including screen-printing meshes or frames, metal parts, plastic components, pharmaceutical tablets, food items, flat or curved surfaces. The choice of coating head, control system and drying module will depend on substrate type, coating material and production volume.

Q: How do I determine the correct coating thickness and number of passes?

A: The correct coating thickness depends on the functional requirement (e.g., protective film, decorative finish, functional layer). Typically, one determines a target thickness and tests sample runs adjusting parameters such as coating speed, spray pattern, number of passes, drying time and substrate load. The machine’s digital control allows presets (for example: 1-15 passes front/back for screen mesh applications). Ensuring uniformity and verifying coating adhesion after drying are essential. Use the machine’s recipe-saving function once optimal parameters are established.

In closing, an advanced automatic coating machine provides manufacturers with the capability to deliver uniform, high-quality coatings with less manual intervention, improved throughput, and readiness for future manufacturing demands. The machine described encompasses robust specifications, digital control, flexible operation and alignment with industry trends. For those seeking reliable coating solutions under the brand NEW STAR, please reach out for further details and support: Contact us.