Which laser engraving plastic sheet actually works for real projects?

2025-11-11

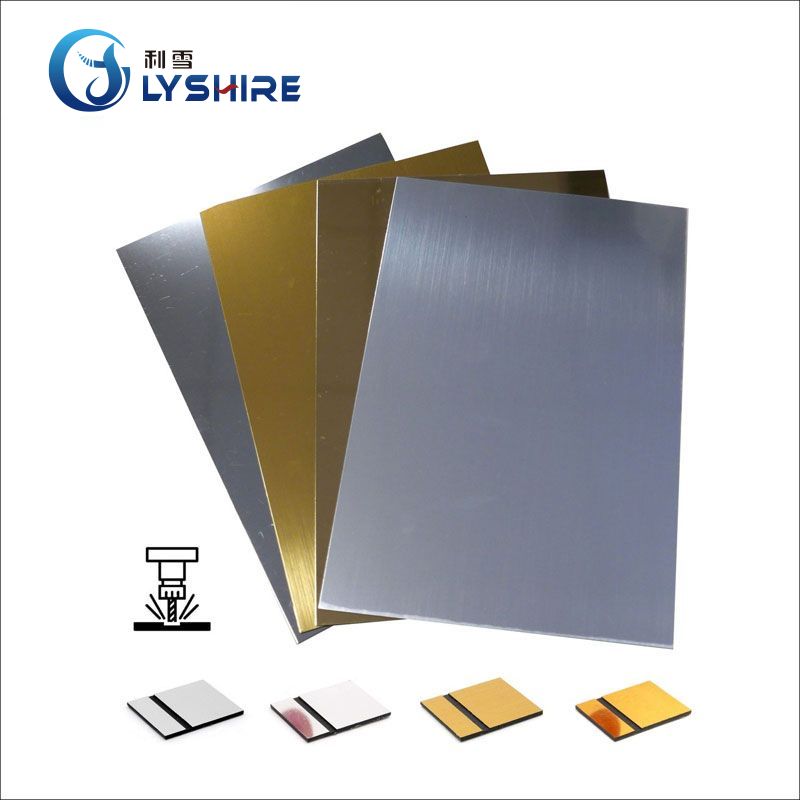

I spend a lot of my week helping sign shops and makers move from test scraps to repeatable production. Along the way, I also work with LYSHIRE on manufacturing runs that keep specs tight and lead times sane. If you are sorting out your first order of Laser Engraving Plastic Sheet, the choices can feel noisy. Here is the practical playbook I use in the shop and at the factory so you can get clean marks, safe cuts, and predictable costs.

What plastic should I pick when I need crisp contrast without drama?

- Cast acrylic gives the sharpest engraved edges on CO₂ lasers and polishes clear when cut. It is my first choice for awards, tags, panels, and backlit work.

- Laminated two-layer engravable sheets create instant color contrast. A thin cap layer ablates to reveal a different core color, perfect for badges and control plates.

- Acetal POM Delrin engraves dark and clean for mechanical parts and snap-fits, though it can smell strong without good extraction.

- PETG engraves acceptably for signage that sees impact and cleaning, but edges are less glossy than acrylic.

- Polycarbonate tends to discolor and edge char on CO₂. I avoid it for cosmetic work unless a fiber or specialty setup is available.

- ABS and HDPE can melt and string. Use only laser-friendly laminates that are formulated for engraving.

- PVC is a hard no on CO₂ because it can release corrosive and toxic gas. Choose PVC-free alternatives.

How do I dial power and speed so the mark pops instead of melting

- Start shallow with one pass and increase in small steps. Depth rarely needs to exceed 0.2–0.3 mm for high readability.

- Use higher speed with just enough power to avoid wide heat-affected zones. If edges look rounded, you used too much power or too slow a speed.

- Drop frequency for vector marking to limit heat build-up. Many CO₂ systems let you lower kHz for cleaner edges.

- Defocus slightly for laminates to peel the cap evenly and reduce streaking.

- Mask glossy faces with paper tape to prevent soot haze, then peel for a pristine surface.

Why do different plastics react so differently to a laser

It comes down to how the polymer absorbs the wavelength and how quickly the material melts or vaporizes. Acrylic fractures cleanly at CO₂ wavelengths and reflows to a glassy edge. Polycarbonate absorbs but chars. HDPE shrinks from heat and smears. Laminates are engineered so the top layer ablates at low energy, exposing a high-contrast core. When I spec a job, I match the polymer to the beam first and styling second.

What real jobs show the differences most clearly

- Control panel plates need high contrast, tiny text, and solvent resistance. I use a laser-grade laminate with a matte cap to avoid glare under task lights.

- Backlit legends look best when I reverse-engrave cast acrylic and infill paint. The diffused edge glows evenly once lit.

- Fixture shims and gears prefer acetal for dimensional stability and a deep, dark mark that stays readable after handling.

Which starting settings make sense before I fine tune

Every machine and lens is different, so I treat these as starting points and run a small swatch first.

| Plastic | Common laser type | Engrave behavior | Cut behavior | Starter settings CO₂ 60W | Shop notes |

|---|---|---|---|---|---|

| Cast Acrylic PMMA | CO₂ | Frosty white mark or clear when reverse | Glossy edge |

Engrave 20–30% power 300–400 mm s Cut 60–80% power 8–15 mm s |

Mask to prevent smoke haze, air assist on |

| Engravable Laminate two-layer | CO₂ | Cap ablates to contrasting core | Clean with right grade |

Engrave 12–20% power 400–600 mm s Cut 40–60% power 10–18 mm s |

Defocus 0.3–0.5 mm for even peel |

| Acetal POM Delrin | CO₂ | Dark crisp mark | Clean functional edge |

Engrave 20–35% power 300–450 mm s Cut 70–90% power 5–10 mm s |

Strong odor extract well |

| PETG | CO₂ | Light mark moderate contrast | Edge not as glossy as acrylic |

Engrave 25–35% power 300–350 mm s Cut 70–85% power 6–12 mm s |

Lower frequency to reduce haze |

| Polycarbonate PC | CO₂ or fiber depending on mark | Risk of browning on CO₂ | Edge may char |

Engrave 10–18% power 300–500 mm s Cut often not recommended cosmetically |

Consider specialized marking if appearance matters |

| ABS general grade | CO₂ | Can melt and smear | Rough edge |

Engrave 10–15% power 400–600 mm s Cut try laminates only |

Use laser-formulated sheets instead |

| PVC | None on CO₂ | Hazardous fumes | Corrosive byproducts | Do not laser | Choose PVC-free materials |

How do I keep parts clean and safe while meeting compliance

- Extraction and filtration keep residues off optics and out of the room. I size airflow for the bed area and check filters on a schedule.

- Material choice avoids chlorine, halogens, and unknown fillers. I ask for PVC-free declarations and SDS with the sheet order.

- Certification packs such as CE and RoHS matter for export builds. With LYSHIRE I keep those documents bundled with batch numbers to simplify audits.

What design tricks make small text and logos read better

- Use single-line or hairline fonts for tiny legends to prevent fill bleed.

- Add a vector kiss-cut around badges to separate soot lines and improve contrast.

- Reverse engrave on the back of clear acrylic and paint infill for rugged front faces.

- Raster dithering at 250–400 dpi on photos keeps tonal transitions smooth without overburn.

How do I order sheets that actually fit my machine and budget

Bed sizes vary and wasted trim eats margin. I like to nest parts tightly, then order sheets slit to bed width so offcuts become useful blanks. With LYSHIRE I can lock in standard thicknesses and colors for stock, request custom core cap combinations for brand palettes, and pull from on-hand inventory when deadlines jump. If you need a price list, lead times, or a small sample kit, I can arrange that before you commit to bulk.

What goes wrong most often and how do I fix it fast

- Melted edges mean power is high or speed is slow. I raise speed first, then drop power.

- Cloudy acrylic points to dirty optics or poor masking. I clean lenses and re-mask with fresh paper tape.

- Uneven laminate peel improves with a slight defocus and consistent air assist.

- Warp after cutting eases if I add micro-tabs or cut in multiple faster passes.

Ready to turn a sketch into production this week

If you want factory-direct sheets that are laser-friendly, color-consistent, and backed by CE documentation, I can help you line up options, samples, and an accurate quote. Tell me your bed size, thickness range, color targets, and quantity plan. If you need custom engraving laminate with a specific cap and core, we can build it. For pricing, stock checks, and sample requests, please contact us and include your application notes so I can recommend the best Laser Engraving Plastic Sheet for the job.