Why Are Light Guide Plates for Printed Covers Essential for Modern Display and Illumination Solutions?

2025-08-12

In today's competitive market, where product presentation and visual impact are key, Light Guide Plates for Printed Covers have emerged as a vital component for both functional and aesthetic purposes. From retail displays to signage, from backlit panels to advertising boards, these plates ensure uniform illumination, enhance printed visuals, and create a lasting impression on viewers. This article provides a comprehensive overview of their function, technical specifications, applications, and the reasons why they have become indispensable.

What Are Light Guide Plates for Printed Covers?

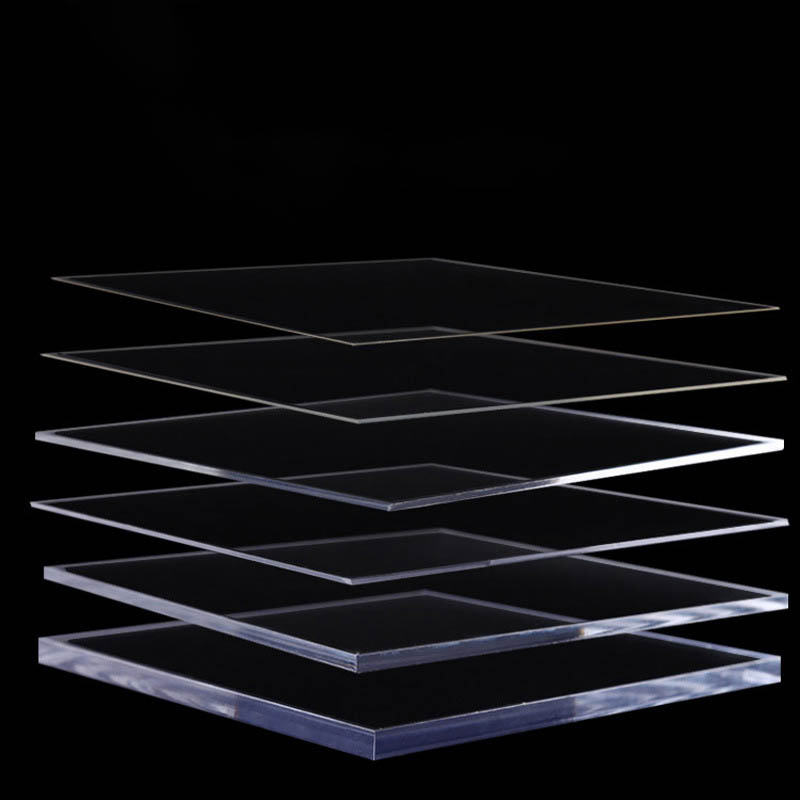

Light Guide Plates (LGPs) for printed covers are optical panels specifically engineered to distribute light evenly across a surface. They are typically used in combination with printed graphics or covers, allowing light from an LED source to spread uniformly and highlight the print without hotspots or uneven brightness.

These plates work on the principle of internal light reflection, where microscopic patterns etched or printed on the plate's surface control the direction and intensity of light dispersion. The result is a bright, balanced, and high-quality illumination effect.

Technical Specifications

Below is a table showcasing typical product parameters for high-performance Light Guide Plates for Printed Covers:

| Parameter | Specification Range | Description |

|---|---|---|

| Material | PMMA (Acrylic) / Polycarbonate | High optical clarity and strength |

| Thickness | 1.5mm – 10mm | Selected based on application and brightness requirements |

| Light Source Compatibility | Side-lit / Edge-lit LED modules | Efficient light transmission and minimal loss |

| Light Transmission Rate | ≥ 92% | Ensures maximum brightness |

| Surface Pattern | Laser micro-dot or screen-printed patterns | Controls light distribution uniformity |

| Maximum Size | Up to 2000mm × 3000mm | For large-format displays |

| Customization | Shape, thickness, dot density | Tailored to design and brand needs |

| Service Life | 5–10 years | Depends on environment and usage conditions |

| Operating Temperature | -20°C to +60°C | Suitable for various climates |

How Do Light Guide Plates for Printed Covers Work?

The core technology behind LGPs involves precision light control:

-

LEDs inject light into the edges of the plate.

-

Micro-patterns on the plate scatter the light at calculated angles.

-

Uniform emission ensures the printed cover is evenly lit.

-

Reflective backing may be added to enhance brightness.

This process eliminates dark spots, optimizes LED efficiency, and delivers a consistent illumination effect.

Best Practices for Selecting Light Guide Plates

When choosing the right LGP for your application, consider:

-

Printing Method – Ensure compatibility with UV, screen, or offset printing.

-

Light Source Quality – Use LEDs with high Color Rendering Index (CRI) for accurate color reproduction.

-

Environmental Conditions – Select materials resistant to temperature fluctuations and UV exposure.

-

Pattern Design – Work with a supplier who can optimize dot distribution for your specific cover design.

FAQ – Light Guide Plates for Printed Covers

Q1: What makes Light Guide Plates for Printed Covers different from regular LGPs?

A1: While regular LGPs focus solely on illumination, Light Guide Plates for Printed Covers are specifically optimized to work with printed graphics. They have tailored dot patterns that ensure even lighting behind detailed prints, avoiding glare and distortion.

Q2: Can I use any type of printed material with these plates?

A2: Yes, but the best results are achieved with high-transmittance, high-quality printed films or covers. Using materials designed for backlighting ensures maximum brightness and accurate color reproduction.

Q3: How long do Light Guide Plates for Printed Covers last?

A3: With proper LED pairing and environmental care, they can last between 5 to 10 years. Their longevity depends on the quality of materials, pattern precision, and operating conditions.

Why Choose Our Light Guide Plates for Printed Covers?

Guangdong Jin Mingwei Photoelectric Technology Co., Ltd. offers industry-leading manufacturing capabilities, advanced pattern design, and strict quality control for every LGP we produce. Our products are tailored to your brand's needs, ensuring your printed covers shine with consistent, vibrant, and energy-efficient illumination.

Contact us today to discover how our Light Guide Plates for Printed Covers can elevate your display solutions and help your visuals stand out in any setting.