Why Is the Folder Gluer Machine the Key to Smarter and Faster Packaging?

2025-10-15

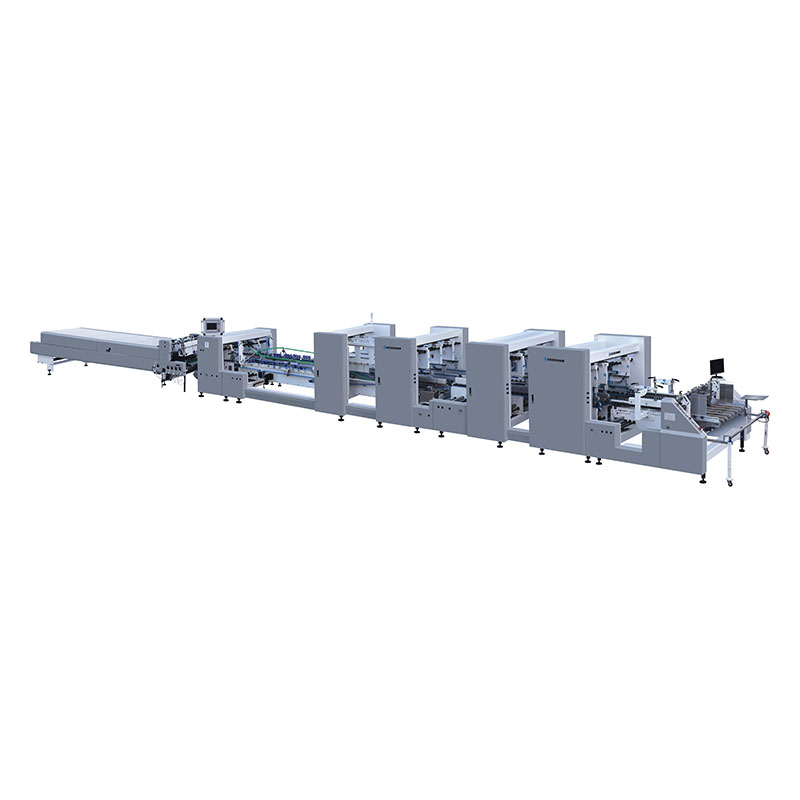

In the modern packaging industry, efficiency, precision, and speed define competitiveness. The Folder Gluer Machine has become an indispensable part of packaging production lines worldwide, revolutionizing how cartons, boxes, and folding packages are assembled. It is designed to fold and glue flat sheets of printed or plain paperboard or corrugated board into fully formed cartons ready for packing and shipping.

Unlike traditional manual methods, a Folder Gluer Machine integrates automatic feeding, folding, gluing, and delivery into a seamless process. This automation drastically reduces labor costs, minimizes errors, and ensures consistent output quality. Whether for pharmaceuticals, cosmetics, food, or e-commerce packaging, this machine ensures precision alignment and perfect adhesion, even at high speeds.

The purpose of this article is to explain what makes a Folder Gluer Machine essential, why it matters for modern manufacturers, and how technological advancements are shaping its future. The article will also introduce the main specifications and parameters of high-performance machines like those developed by NEW STAR, along with professional answers to frequently asked industry questions.

Why Is the Folder Gluer Machine So Important for Today’s Packaging Industry?

The global packaging market is rapidly evolving due to increasing demand for sustainable, cost-effective, and customized packaging solutions. As consumer brands focus more on presentation and protection, manufacturers require equipment that offers both precision and scalability. The Folder Gluer Machine fulfills these needs through several critical advantages:

-

High-Speed Production – Modern folder gluers can achieve speeds of up to 400 meters per minute, ensuring quick turnaround times even for large orders.

-

Versatile Compatibility – Capable of processing various board types—from solid cardboard to corrugated and laminated paper—these machines meet diverse packaging requirements.

-

Accurate Folding and Gluing – Precision-controlled systems guarantee exact creasing and folding lines, ensuring the finished product is perfectly aligned.

-

Reduced Waste and Downtime – Automation minimizes material waste, while easy setup systems shorten changeover times between box types.

-

Enhanced Sustainability – Many modern models feature eco-friendly adhesive systems and low-energy drives, supporting greener production processes.

By combining digital controls, servo-driven motors, and intelligent monitoring systems, Folder Gluer Machines deliver consistent quality while lowering operational costs. For manufacturers, this translates to higher productivity, reduced rework, and improved customer satisfaction.

What Are the Key Specifications and Technical Parameters of a High-Performance Folder Gluer Machine?

To ensure optimal performance and adaptability, choosing the right Folder Gluer Machine requires understanding its technical details. Below is an overview of typical specifications found in high-end models designed for commercial and industrial use:

| Parameter | Specification Range / Description |

|---|---|

| Feeding System | Automatic continuous feeding with friction belt or suction feeder |

| Max. Sheet Size | 1100 x 800 mm (customizable for large formats) |

| Min. Sheet Size | 150 x 100 mm |

| Material Thickness | 200–800 g/m² (paperboard, corrugated board) |

| Folding Speed | Up to 400 m/min |

| Folding Section | Pre-folding & final folding stations with adjustable belts |

| Gluing Type | Cold glue / Hot melt glue (optional dual system) |

| Glue Application Control | Electronic sensor-based precision system |

| Delivery System | Automatic counter and batch stacking |

| Power Requirement | 10–15 kW (depends on model configuration) |

| Control System | PLC with touchscreen HMI for parameter setup and fault diagnostics |

| Optional Features | Crash lock bottom, 4/6 corner folding, side register system, barcode detection |

These specifications demonstrate that modern Folder Gluer Machines are engineered for high precision, low maintenance, and modular flexibility. They allow seamless adaptation to multiple box designs—whether straight-line, crash lock, or 4/6-corner types—making them ideal for mass production with rapid design switching.

How Is Technology Shaping the Future of Folder Gluer Machines?

The future of folder gluing technology is moving toward smart automation, digital integration, and sustainability. As manufacturing embraces Industry 4.0, Folder Gluer Machines are evolving in three primary directions:

-

Digital Automation and Smart Sensors

-

Advanced sensors and IoT integration now allow real-time monitoring of glue application, folding precision, and defect detection.

-

Machine learning algorithms can predict maintenance schedules, reducing downtime and preventing costly interruptions.

-

-

Modular and Customizable Designs

-

Manufacturers increasingly request modular machines that can be upgraded with extra stations for specialized folding or embossing.

-

This flexibility allows easy adaptation to different packaging materials and evolving market needs.

-

-

Eco-Friendly Manufacturing Trends

-

With global emphasis on sustainability, Folder Gluer Machines now feature energy-efficient motors, solvent-free adhesives, and recyclable materials.

-

Integrated glue-saving systems and low-waste designs help manufacturers meet environmental standards while cutting operational costs.

-

In the next decade, Folder Gluer Machines are expected to merge even more with AI-driven control systems and cloud-based quality management platforms, allowing production data to be shared across global factories instantly. This transformation will empower packaging producers to maintain uninterrupted, high-efficiency operations with precise process control.

Frequently Asked Questions About Folder Gluer Machines

Q1: What types of packaging can a Folder Gluer Machine produce?

A Folder Gluer Machine is capable of producing a wide range of packaging types including straight-line boxes, crash lock bottom boxes, 4-corner and 6-corner cartons, and envelope-style boxes. These designs are used in industries like pharmaceuticals, cosmetics, food, beverages, and electronics. The versatility comes from its modular folding stations and adjustable tooling systems that adapt to various sizes and materials.

Q2: How can a manufacturer choose the right Folder Gluer Machine for their production line?

Choosing the right machine depends on production volume, box type, material thickness, and customization requirements. For high-volume straight-line production, a high-speed automatic machine with servo control is ideal. For diverse designs like multi-corner boxes, a machine with extended folding sections and precise alignment systems is recommended. It is crucial to evaluate the glue system type, feeding accuracy, and folding precision before purchasing.

Why Choose NEW STAR Folder Gluer Machines and What Makes Them Stand Out?

Among leading packaging machinery manufacturers, NEW STAR has established itself as a trusted name recognized for quality, innovation, and customer service. NEW STAR’s Folder Gluer Machines are built with advanced servo technology, precision-engineered components, and a user-friendly interface that simplifies operation even for complex packaging formats.

Each model is tested for durability and accuracy, ensuring stable performance under continuous high-speed production. The company’s focus on research and development ensures that every new generation of machines incorporates cutting-edge features such as smart glue monitoring, fault detection systems, and eco-friendly adhesive technologies.

Furthermore, NEW STAR’s after-sales support provides professional installation, operator training, and ongoing maintenance consultation—helping businesses maximize productivity from day one.

As packaging continues to evolve toward faster, smarter, and greener manufacturing, NEW STAR remains dedicated to supporting global customers with innovative Folder Gluer solutions that balance speed, precision, and sustainability.

For businesses seeking to upgrade their packaging efficiency and stay ahead of industry trends, NEW STAR offers the expertise and reliability needed to transform production capabilities.

Contact us to learn more about how NEW STAR’s Folder Gluer Machines can enhance your packaging operations and drive your business toward smarter, more sustainable manufacturing.